Years of Experience

and extensive

Portfolio Product

WESTERMANN believes in continuous project support from task analysis to final installation. Our trained personnel have profound expertise in the current standards and legal requirements and can provide advice on aspects of both design and economy. The concepts are individually developed and the final installation will incorporate products and elements, which are acoustically effective and sound insulation tested. These include products of well-known manufacturers as well as our own products, which are processed to our customer’s specifications in our factory. Our portfolio includes:

- Cupboard fronts

- Wall cladding

- Ceilings, sails, baffles

- Individual furniture items

- Room-in-room systems

- Modular office partitions

- Broadband compact absorbers

- Ceiling edge absorbers

- Furniture applications

- Wooden doors

Technical feasibility

and maximum

economic efficiency

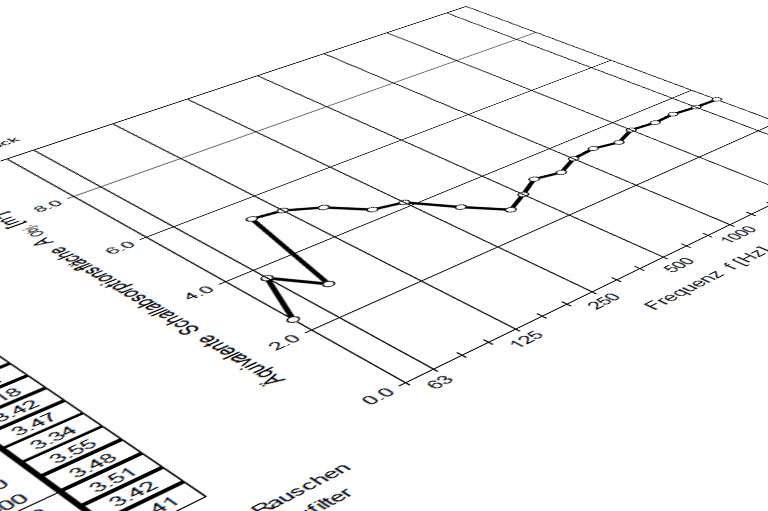

A complete range of building physics and legal issues must be fulfilled for the development of effective acoustic solutions. Whether it is a question of αw-values, acoustic relevant DIN standards or VDI regulations relating to acoustics: WESTERMANN can rely on many years of experience in dealing with the latest standards and the implementation of requirements in building physics.

We can perform measurement surveys for building and interior acoustics as well as pollution-related analyses according to our customer’s specific requirements. These serve to fully understand the acoustic characteristics and to effectively identify potential sources of errors as well as ensure design optimisation and thus guarantee maximum economic efficiency.

Technical

feasibility

and maximum

economic

efficiency

Special materials

and professional

processing

Possibilities in the field of acoustic and sound insulation for interior design concepts by far exceed the classical joinery solutions of the past and lend themselves to the use of a variety of materials. WESTERMANN has incorporated widely varying materials over the years, and combined these to provide successful acoustic solutions. The following materials are used to meet acoustic and sound insulation requirements:

- Wood

- Metal

- Acrylic glass

- Foils

- Glass

- Textiles

- Plaster

- Technical fibrous fabrics

WESTERMANN is certainly the right choice when it comes to manufacturing specific materials or processing industrially prefabricated acoustic products and sound insulation elements. The latest machinery has been installed in our production plant, which can handle every material to produce the optimal, acoustically effective solution.

Development of

customised acoustic

solutions

Development of

customised acoustic

solutions

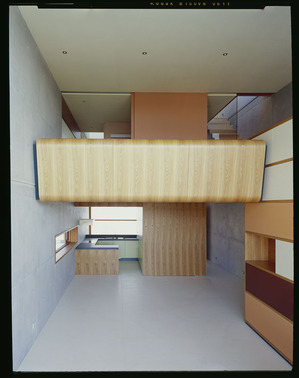

The considerable number of customised acoustic solutions, which we have provided over the past few years, is evidence of the relevance of acoustic and sound insulation issues. This has led to the development of unique designs incorporating a variety of absorbers and components and the combination of acoustically effective sound insulation elements to meet design and safety standards. These satisfy the customer’s specific requirements and fit harmoniously in to the given interior design concepts.

If you are looking for an extraordinary acoustic solution, WESTERMANN is the right address. Please contact us for a consultation, which we would be pleased to offer.

We only hear good news:

Selected WESTERMANN references

for acoustic and sound insulation

Uni Mannheim

Kammermusiksaal Kronberg

Integrierte Gesamtschule, Frankfurt am Main-Riedberg

Revitalisierung Guesthouse

Endress + Hauser

Plenarsaal Mainz

Verwaltungsgebäude Walldorf

Bildungscampus Heilbronn III, Gebäude R,S,T

Neubau Stadthalle Cham

Grundschulen München

Stadtwerke Karlsruhe

Stadtbibliothek Rottenburg

Roche Elsässertor Basel

Vector Firmenzentrale, Stuttgart

Bildungscampus Heilbronn, BT III

Mathematikon MUH, Heidelberg

Bilungscampus Heilbronn BT II

Unibibliothek Heidelberg, Geb. Triplex

GFT Firmenzentrale

Bundesverfassungsgericht BVG, Karlsruhe

Räumliches Bildungszentrum Biberach

Konica Minolta, Langenhagen

Rathaus Neckarwestheim

Habermaaß Neubau Verwaltungsgebäude Leschenhof, Bad Rodach

Königin-Katharina-Stift Gymnasium, Stuttgart

Rechtsanwaltskanzlei Schaudt, Stuttgart

Festo AG - Besprechungskabinen

Bundesgerichtshof, Karlsruhe

Neubau ADAC-Zentrale, München

Bildungscampus Heilbronn

Lässing Müller Werbeagentur

Erweiterung und Umbau Hauptstelle Kreissparkasse Göppingen

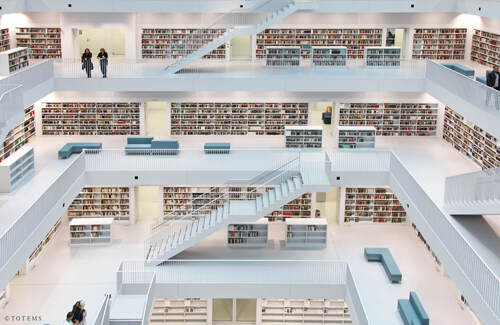

Stadtbibliothek, Stuttgart

Oberfeldwebel-Schreiber-Kaserne, Immendingen

Universitätsklinikum Tübingen

Pausa Tonnenhalle, Mössingen

ENBW Leitstellen - Ravensburg, Heilbronn, Esslingen

Neubau Rathaus Schefflenz

Lycée Technique de Lallange

Kinderhaus Kernen

KfW Westarkade, Frankfurt am Main

Porsche Museum

Verwaltungsgebäude Im Quadrat, Aalen

Ellenrieder Gymnasium, Konstanz

Fachhochschule Neu-Ulm

Imtech, Stuttgart

MVV Mannheim

Landesmesse Stuttgart

Bürogebäude Haba, Bad Rodach

Landratsamt Tübingen

Neubau Mercedes-Benz Museum Stuttgart

Gemeinschaftszollanlage Rheinfelden-Warmbach

Neubau Verwaltungsgebäude Schubert, Crailsheim

Gymnasium Erding

Verwaltungsgebäude BKK, Villingen- Schwenningen

Wohnhaus W.

Albert-Schweitzer Gymnasium

Wohnhaus D.

Krystaltech Lynx European Headquarters

Erweiterung Sparkassen Versicherung